Understanding Oxygen Analyzer: An Overview

Introduction to Oxygen Analyzers

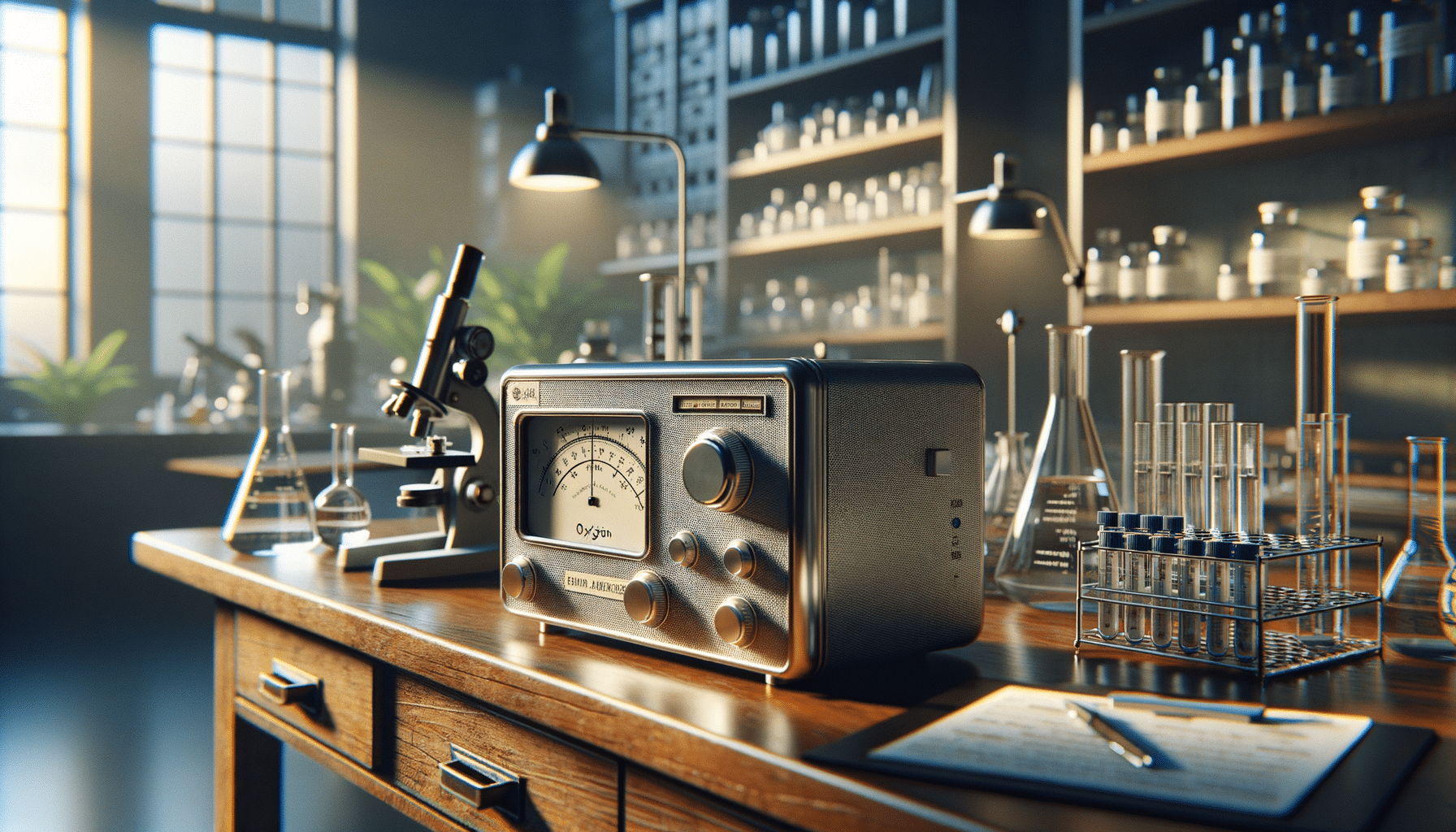

Understanding the role of oxygen analyzers is crucial in various industries where accurate measurement of oxygen levels is vital. These instruments, whether referred to as a headspace oxygen analyser, headspace oxygen analyzer, analyzer oxygen, or simply oxygen analyzer, serve the fundamental purpose of determining the oxygen concentration in a given environment. This is particularly important in sectors like food packaging, pharmaceuticals, and industrial processes, where oxygen levels can impact product quality and safety. The difference in spelling—analyser versus analyzer—often depends on regional preferences, but the functionality remains consistent.

Types and Applications of Oxygen Analyzers

Oxygen analyzers come in various forms, each tailored to specific applications. Common types include paramagnetic, zirconia, and electrochemical sensors. Each type has its unique mechanism for detecting oxygen levels, offering versatility across different environments. For instance, paramagnetic analyzers are known for their precision and are often used in laboratory settings. Zirconia sensors, on the other hand, are favored in high-temperature environments like combustion processes because of their robustness.

The applications of oxygen analyzers are vast:

- In the food industry, they ensure the freshness and longevity of packaged goods by monitoring the oxygen levels within sealed packages.

- In medical settings, they are vital for maintaining the correct oxygen concentration in breathing gases.

- In the petrochemical industry, they help prevent combustion and ensure safety by monitoring oxygen levels in flammable environments.

Each application benefits from the precise measurement capabilities of these instruments, underscoring their importance across various sectors.

How Oxygen Analyzers Work

The working principle of oxygen analyzers varies depending on the type, but they all aim to provide accurate oxygen measurements. Paramagnetic analyzers exploit the fact that oxygen molecules are attracted to magnetic fields. By measuring changes in magnetic fields, these analyzers can determine oxygen levels with high precision.

Electrochemical sensors, another popular type, use a chemical reaction to produce an electrical current proportional to the oxygen concentration. This method is often used in portable devices due to its simplicity and reliability.

Zirconia sensors, suitable for high-temperature environments, rely on the movement of oxygen ions through a zirconia ceramic cell. The difference in oxygen concentration across the cell generates a voltage that can be measured to determine oxygen levels.

Despite the differences in technology, all these analyzers share the goal of delivering reliable oxygen measurements crucial for maintaining safety and quality in various applications.

Choosing the Right Oxygen Analyzer

Selecting the appropriate oxygen analyzer depends on several factors, including the specific application, environmental conditions, and required accuracy. When choosing an oxygen analyzer, consider the following:

- The environment: Is it high-temperature or corrosive? This will determine whether a zirconia or electrochemical sensor is more suitable.

- Accuracy requirements: Some applications, like medical or laboratory settings, demand higher precision.

- Portability: For fieldwork, a portable electrochemical sensor might be more practical.

Moreover, understanding the maintenance needs and lifespan of the sensor technology is important, as it affects the long-term cost and reliability of the analyzer. Consulting with experts and reviewing product specifications can help make an informed decision, ensuring the chosen analyzer meets all operational requirements.

Conclusion: The Future of Oxygen Analyzers

As technology advances, oxygen analyzers are becoming more sophisticated, offering enhanced features such as real-time data logging and wireless connectivity. These improvements are making oxygen analyzers more user-friendly and efficient, allowing for seamless integration into automated systems. The demand for such advanced features is growing, particularly in industries that prioritize safety and quality control.

Looking ahead, the development of more compact and energy-efficient designs is likely to expand the applications of oxygen analyzers even further. As industries continue to evolve, the role of oxygen analyzers in ensuring safety and quality remains critical, highlighting their enduring relevance in modern technological landscapes.